STERIGERMS technology has been developed on the basis of stringent specifications tailored to the goals, practical uses and constraints of the French Navy. The life expectancy goals combined with the constraints of an aggressive environment (saline air//humidity) and specific uses made of the equipment have forced STERIGERMS staff to design and build a highly efficient waste treatment system.

The STERIGERMS technology consists of isolating the clinical waste in a specially designed Steribag, so that it can be heated to a temperature of 150° C and then compressed in order to reduce the volume of the waste by up to 80%. This treatment produces an inert disk, which has been turned into household waste, containing totally neutralised waste such as containers with needles, syringes, scalpels, sharp blades, dressings, protective clothing, any glass which has contained blood or secretions, catheters, tubes etc., which then can be disposed of along with any household waste,

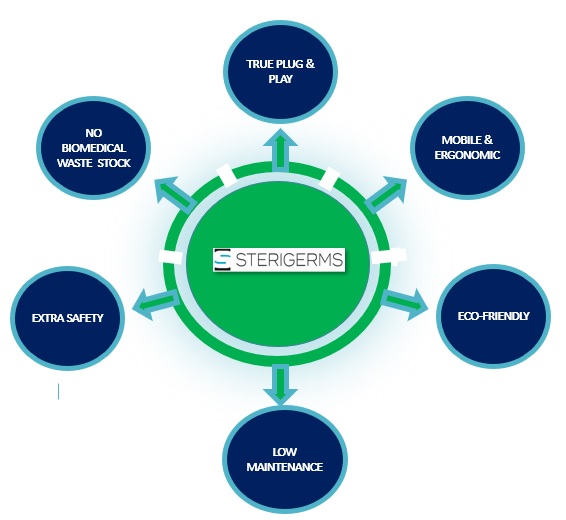

Sterigerms machines are compact and mobile, do not require any water supply, can be installed and uninstalled quickly anywhere, and can easily be moved around within a facility, offering maximum safety for both the community and the environment.

In addition to all this, the Sterigerms machines development plan took our customers’ lack of available resources into account, and so maintenance operations are kept to the bare minimum.

The STERIGERMS system has unique properties which make it an excellent solution for specific uses in restrictive environments.